Inspecting solid carbide cutting tools is of paramount importance

in the manufacturing and machining industries. Proper inspection of these tools ensures the quality of the machining process and the finished products. Here’s why inspecting solid carbide cutting tools is crucial:

Quality Assurance: Solid carbide cutting tools play a critical role in achieving precise and accurate machining results. Inspecting these tools ensures that they meet the required specifications and tolerances, maintaining the quality of the machined components.

Optimal Performance: Well-inspected carbide cutting tools perform optimally, resulting in efficient material removal, smooth surface finishes, and extended tool life. Proper inspection helps identify any issues that could lead to subpar performance or premature tool wear.

Process Consistency: Consistency in tool quality leads to consistency in machining processes. By inspecting carbide cutting tools, manufacturers can minimize variations in cutting performance and reduce the risk of defects or inconsistencies in the finished products.

Tool Life Optimization: Effective inspection allows manufacturers to monitor tool wear and performance degradation over time. By identifying signs of wear early, machining operations can be adjusted or tools replaced before they fail, maximizing tool life and minimizing downtime.

Cost Efficiency: Carbide cutting tools are often expensive investments. Regular inspection helps ensure that these tools are used efficiently and to their full potential, reducing the need for premature replacements and saving costs in the long run.

Prevention of Work Piece Damage: Damaged or worn carbide cutting tools can lead to poor surface finishes, dimensional inaccuracies, and even work piece damage. Inspection helps prevent such issues by detecting problems before they impact the final product.

Reduced Scrap and Rework: Defective or worn-out cutting tools can result in scrapped parts or components that require rework. Inspection minimizes the chances of producing faulty parts, reducing waste and the need for additional work.

Safety: Worn or damaged tools can increase the risk of accidents, such as tool breakage during machining operations. Proper inspection helps identify potential safety hazards and prevents accidents in the manufacturing environment.

Process Optimization: Inspection data can be analyzed to gain insights into tool wear patterns, cutting conditions, and machining parameters. This information can be used to fine-tune machining processes, optimize tool usage, and improve overall manufacturing efficiency.

Quality Control Documentation: Inspection records and data provide a documented history of tool quality and performance. This documentation is important for quality control audits, compliance with industry standards, and traceability in case of issues.

Customer Satisfaction: When solid carbide cutting tools are inspected and maintained properly, they contribute to producing high-quality components. This, in turn, leads to satisfied customers who receive products that meet their specifications and expectations.

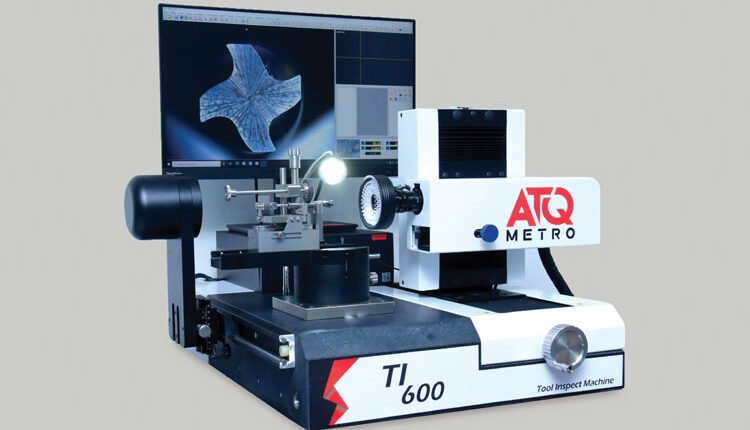

ATQ Cutting Tool Inspection Machine Excellence in Solid Carbide Tool Inspection

A Cutting Tool Inspection Machine is specialized equipment used in manufacturing and machining industries to inspect and evaluate cutting tools. Cutting tools such as drills, end mills, reamers, taps and form tools are critical components in machining processes. Ensuring their quality and precision is essential to maintain consistent and accurate manufacturing processes.

The Cutting Tool Inspection Machine is designed to perform various inspections and measurements on cutting tools to verify their dimensions, geometry, and overall quality. These machines are equipped with advanced sensors, cameras, and measurement devices that allow for precise measurements. Some common features and functions of a Cutting Tool Inspection Machine include:

Visual Inspection: High-resolution cameras and imaging systems are used to capture detailed images of the cutting tools. These images can be analyzed to identify surface defects, wear patterns, and other imperfections that could affect the tool’s performance.

Accurate and Precise Measurements: ATQ Tool Inspect Machine has high-resolution cameras, precision stages, and advanced optics to measure dimensional characteristics of tool with high accuracy and repeatability. This is crucial for ensuring that manufactured tools meet specified tolerances and quality standards.

Dimensional & Geometry Measurements: Cutting Tool Inspection Machines can measure various dimensions of cutting tools, such as Helix angle, Axial relief angle, Primary relief angle, secondary relief angle and Tilting Edge angle , Primary and Secondary Land , Front Rake, Pitch Angle, Web Thickness, Rake Angle, Core Dia, Centre offset etc. These measurements help ensure that the tools meet the required specifications.

Documentation, Traceability & Reporting: The measurement data collected by the machine can be analyzed to generate reports and statistics about tool quality and performance. This data can assist in quality control and process improvement efforts.

Comparative Analysis: ATQ Tool Inspect can compare the measurements of a tool against a reference model or master tool to determine the degree of wear or deviation from the original design.

Cost Savings: While ATQ Tool Inspect can be a significant investment, they can lead to long-term cost savings by reducing the need for rework, minimizing scrapped parts, and improving overall process efficiency.

Overall, ATQ Cutting Tool Inspection Machines play a critical role in maintaining the quality and accuracy of cutting tools used in manufacturing processes. By ensuring that cutting tools are in optimal condition, manufacturers can achieve consistent results, improve efficiency, and reduce the likelihood of defects and downtime.

[Courtesy: ATQ Metro]