Deep-Hole Drill, as initially invented for ‘Gun-Drilling’ application in Europe during the Second World War; and since then is popular as ‘Gun-Drill’. However, over last 75 years, its applications are extended in Auto Industry and other engineering metal cutting industries for Deep Hole Drilling. Still these Deep-Hole Drills are yet popularly called as ‘Gun-Drills’, even if used for other applications.

Deep-Hole Drill, as initially invented for ‘Gun-Drilling’ application in Europe during the Second World War; and since then is popular as ‘Gun-Drill’. However, over last 75 years, its applications are extended in Auto Industry and other engineering metal cutting industries for Deep Hole Drilling. Still these Deep-Hole Drills are yet popularly called as ‘Gun-Drills’, even if used for other applications.

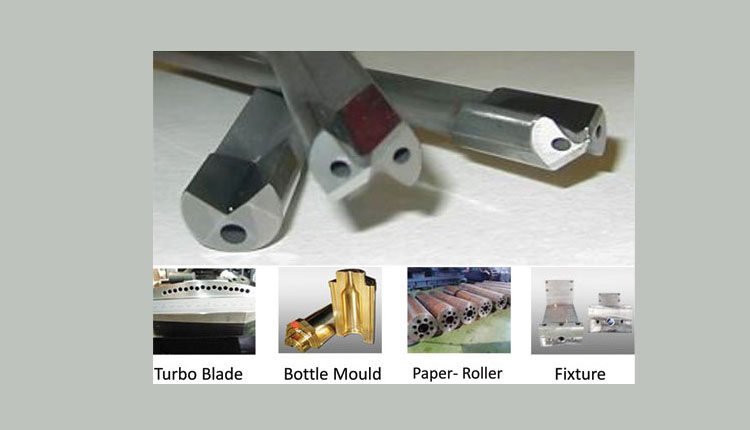

Accusharp Cutting Tools have entered into this new segment of Round Tools for Deep-Hole Drilling applications. The applications are for deep holes drilling on Crankshaft, Engine blocks, Turbo Blades, Paper Rollers, Machine Tools, Fixturing, etc.

Standard geometry for Gun-Drill has been shown herewith. However, it may change according to its applications for different work materials, and machining parameters. Moreover, any change in the cutting edge geometry will have effect on bore surface finish, geometrical accuracy, drill centring, chip shape, chip removal, process reliability, and useful life of the drill, etc.

Our standard grinding geometry can take care virtually of all drilling operations successfully. However, for any special working conditions, like deep drilling long chipping material work piece or material that is difficult to machine, we design and manufacture Gun-Drills with special geometries, accordingly.

Our present range of Gun-Drills is of Diameters between 4 and 30 mm., having length up to 1000 mm.

Trouble shooting guide:

| Problem: | Probable Cause: | Probable Solutions: |

| Premature drill point wear | Machine vibrations, Loose clamping of the work piece. |

|

| Crater wear | Improper guidance for the drill into the work piece |

|

| Groove marks on the hole | Rubbing of the drill in the hole |

|

| Hole entry dia. enlarged | Tool set up error |

|

Moreover, guidance from our technical experts would always be available for any critical problems other than the above common issues to resolve.