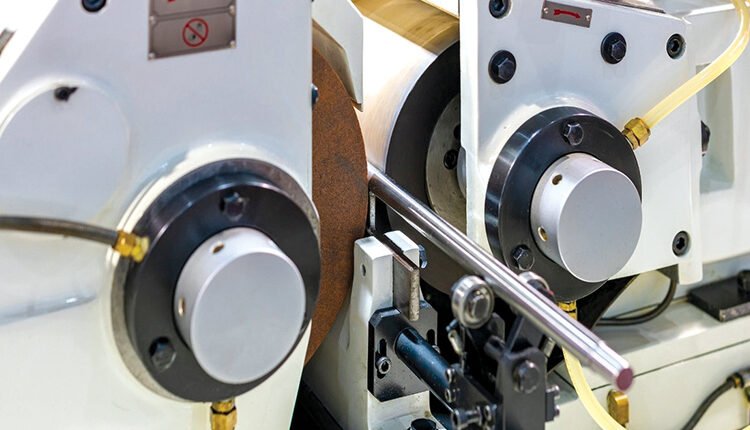

Centreless grinding is one of the most efficient and versatile grinding processes in modern manufacturing. Unlike conventional cylindrical grinding, where the workpiece is held between centers or in a chuck, centreless grinding eliminates the need for any fixturing or workholding. Instead, the workpiece is supported between a grinding wheel, a regulating wheel, and a work rest blade. This unique setup makes centreless grinding ideal for producing high-precision cylindrical parts at scale, with tight tolerances and superior surface finishes.

Understanding the Centreless Grinding Principle

At the heart of the process lies the absence of centers. The workpiece is placed on a work rest blade positioned between a fast-rotating grinding wheel and a slower-rotating regulating wheel. The regulating wheel controls the rotation and feed of the part, while the grinding wheel removes material.

The key advantages of this principle are:

• No requirement for clamping or fixturing.

• Continuous feeding of parts for mass production.

• Ability to process very small, thin, or delicate workpieces without distortion.

Types of Centreless Grinding

1 Through-Feed Grinding

In through-feed grinding, the workpiece is fed axially between the wheels and exits on the other side. This method is best suited for simple cylindrical parts without shoulders.

Example: Automotive fasteners, shafts, and pins are mass-produced using through-feed grinding for speed and consistency.

2 In-Feed (Plunge) Grinding

Here, the regulating wheel moves laterally, allowing grinding of parts with shoulders, complex profiles, or varying diameters.

Example: Components like valve seats, pump parts, and bearing races are finished using plunge grinding.

3 End-Feed Grinding

This technique involves feeding the workpiece axially until it contacts a stop. It is commonly used for tapered components.

Example: Tapered rollers for bearings often undergo end-feed grinding.

Equipment and Setup Nuances

The quality of centreless grinding is heavily influenced by machine setup. Key elements include:

• Grinding Wheel: Performs the actual cutting, typically made of aluminum oxide or CBN for hard materials.

• Regulating Wheel: Controls workpiece speed and feed; usually made of rubber-bonded abrasive.

• Work Rest Blade: Supports the workpiece; its geometry and

material (often carbide) directly affect accuracy.

Proper alignment of the wheels and blade is critical. Even minor errors in height setting can result in taper, chatter, or out-of-roundness.

Applications Across Industries

Centreless grinding has found widespread application in industries demanding precision and productivity:

• Automotive: Shafts, gear components, transmission parts.

• Aerospace: Hydraulic rods, landing gear pins, bushings.

• Medical: Orthopedic pins, surgical instruments.

• Bearing Industry: Rollers, races, and cages.

• General Engineering: Fasteners, spindles, and tools.

Advantages of Centreless Grinding

• High Productivity: Continuous operation allows rapid production of thousands of identical parts.

• Tight Tolerances: Capable of achieving roundness within 0.5 microns and surface finishes below 0.2 µm Ra.

• Versatility: Processes parts from a few millimeters to several hundred millimeters in diameter.

• Cost-Effective: Eliminates workholding fixtures, reducing setup costs.

• Delicate Part Handling: Ideal for slender or brittle workpieces that would distort under clamping.

Challenges and Nuances

While highly productive, centreless grinding is also a process of nuances. Some of the key challenges include:

• Setup Sensitivity: Achieving accurate alignment between the grinding wheel, regulating wheel, and work rest is critical.

• Wheel Dressing: Both grinding and regulating wheels require frequent dressing to maintain profile and efficiency.

• Process Stability: Issues like chatter, lobing, or barrelling can occur if setup or wheel condition is not optimal.

• Part Geometry: Not ideal for parts with interrupted surfaces, deep shoulders, or heavy stock removal.

Case Examples

Automotive Shafts: In high-volume automotive production, centreless through-feed grinding is used to finish transmission shafts to micron-level tolerances. This reduces friction and ensures long service life.

Medical Implants: Titanium orthopedic pins require centreless plunge grinding for precision diameters and ultra-smooth finishes that improve biocompatibility.

Bearing Rollers: Millions of taper rollers undergo end-feed centreless grinding daily, ensuring the precision and reliability of bearings used in heavy industries.

Recent Advancements in Centreless Grinding Technology

• CNC-Controlled Centreless Grinders: Provide automatic setup, wheel adjustment, and adaptive control for higher accuracy.

• Advanced Wheel Materials: CBN and diamond wheels extend tool life, reduce dressing frequency, and improve finish.

• Automated Loading Systems: Robots and conveyors increase efficiency in high-volume production.

• In-Process Gauging: Real-time feedback allows correction during grinding, improving consistency.

• Eco-Friendly Coolants: Water-based and minimum quantity lubrication (MQL) reduce environmental impact while maintaining surface integrity.

The Future of Centreless Grinding

The future of centreless grinding lies in automation, digitalization, and hybridization. Machines are increasingly equipped with AI-driven analytics to predict wheel wear, optimize dressing cycles, and reduce downtime. Hybrid grinders capable of combining centreless grinding with polishing or superfinishing are also emerging. Sustainability is another driver, with manufacturers seeking energy-efficient machines and greener coolants.

Conclusion

Centreless grinding is a process of both simplicity and sophistication. By eliminating the need for workholding, it enables high-speed, high-precision production of cylindrical parts across industries. Yet, its success hinges on mastering setup, wheel dressing, and process control—factors that separate average results from world-class performance.

With advancements in CNC control, automation, and new abrasive technologies, centreless grinding continues to evolve, securing its role as a cornerstone in precision manufacturing.